The pandemic is placing additional demands on the maintenance of production equipment and machinery. The availability of equipment must continue to be ensured even during these difficult times. Many facilities in areas such as food production, recycling, wastewater treatment, energy production and raw material extraction continue to run at full capacity.

The maintenance of these systems, in particular the relubrication of bearing points, must be ensured without restriction despite the Covid-19 situation. An unplanned machine breakdown would pose further problems for the operators. Uncertain spare-part supply chains or difficult access to production halls due to Coronavirus safety measures and travel restrictions exacerbate the problem.

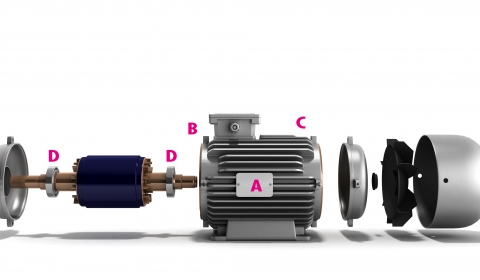

simalube lubricant dispenser

The automatic, self-acting simalube lubricant dispenser is the perfect tool for this. Lubrication points are automatically lubricated by the device for the preselected runtime (1-12 months). In principle, no mandatory inspections of the system by maintenance personnel are necessary during this period. The easiest way to extend the time the dispenser lasts before having to change it is to always use the largest possible dispenser (simalube 250ml).

Sick maintenance workers

Due to the pandemic, it could now be the case that maintenance workers cannot replace the lubricant dispensers at the scheduled time due to a positive PCR test result, requiring them to go into isolation or quarantine. The following section describes how simalube can easily incorporate additional security that does not incur any additional operating costs after the initial installation.

Guaranteed emergency lubrication through multiple adapters

Instead of lubrication with a single simalube lubricant dispenser, lubrication can be carried out simultaneously on the same lubrication point by two or four lubricant dispensers. A 2-way or 4-way adapter is used for this.

The dispensers are set to double or quadruple the running time so that the original lubricant quantity is applied at the lubrication point. The dispensers can also be started as "half-time - time-delayed". This guarantees that in the event of a delayed dispenser change due to Coronavirus, at least one dispenser will continue to dispense and the lubrication point will continue to be supplied with at least ½ of the lubrication quantity meaning it will therefore not "run dry". For the "time-delayed" operation, we recommend fitting check valves or, preferably, simalube IMPULSE, as these already have built-in check valves. This allows the dispensers to be changed without grease leaking, even under counter-pressure from the lubrication point. All these methods increase the dependability of the already reliable simatec products. In (long-term) operation, no more lubricant dispensers are required than with a standard "single" dispenser installation.

Example: “safe” pump lubrication at 3 month setting (125ml)

A pump drive train is currently lubricated with a simalube 125ml dispenser on a 3-month setting. In order to make this critical lubrication point even more secure and more independent (in terms of time), a 2-way adapter with dispensers for a running time of 6 months or a 4-way adapter with dispensers for a running time of 12 months are installed. A 2-way adapter, simalube 250ml version on a 12-month runtime can also be installed. The configurations are very diverse and can be individually adapted to the specific security needs. simatec's customer service team or a simalube dealer will be able to provide you with expert advice.

"Time-delayed" dispenser change/start

For the "time-delayed" dispenser change (half-time), it is best to contact simatec customer service for instructions. The start-up procedure is a little more complicated here. To begin the "time-delayed" version, two different dispenser sizes must initially be started at the same time. For the above example, one dispenser of 125ml for 6 months and one dispenser of 60ml for 3 months will be used. After 3 months, the emptied 60ml dispenser is replaced by a 125ml dispenser set to 6 months, thereafter an emptied 125ml dispenser set to 6 months is replaced every 3 months. In this way, the dispensers always run empty "overlapping" halfway through and minimum lubrication (50%) is guaranteed in each case.

Your opinion on this article