Every wind turbine, regardless of its design, has a large number of lubrication points that have to be supplied at regular intervals. Since wind turbines are often located in remote locations, these maintenance tasks are always challenging and involve a great deal of time and money. Strong fluctuations in temperature, moisture, wetness and extreme loads create problems for the systems. To avoid possible damage, lubricants must therefore be available at the right time and in the right amount.

Lubrication

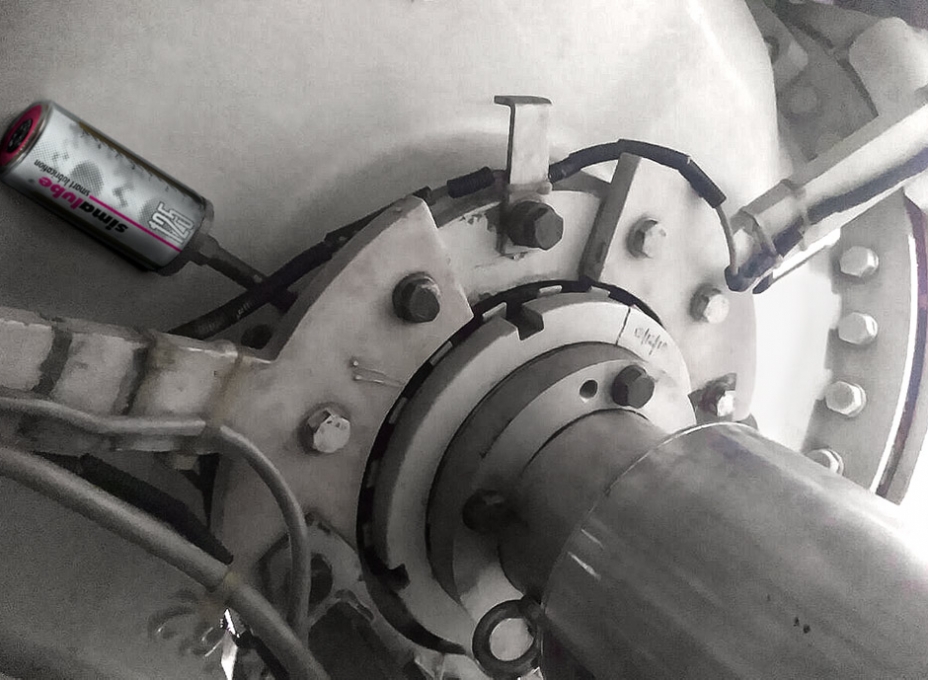

Bearings

Challenges

- High demands on the availability of the systems

- Large seasonal temperature fluctuations

Benefits

- Increased operational security

- Less downtimes

- Permanent supply of lubrication points that are difficult to access

- Less time spent on maintenance

- Reduction of wear and longer component life

Solution

- simalube 60, 125 and 250 ml

- Installation directly, the lubricant is often fed to the lubrication point via a lubrication pinion.

Videos

Creative installations Vol. 1

Creative installations Vol. 2

Creative installations Vol. 3

- Generators

- Wind turbines on-shore

- Wind turbines off-shore

Downloads