The use of simalube significantly reduces maintenance costs. By continuously releasing the lubricant, simalube extends the lifespan of bearings, chains, guides, gears and other mechanical parts. The dispensers are also ideal for use in hard-to-reach places. With the installation of the simalube, the time spent by employees in the danger areas is reduced. Regular, manual lubrication of the systems with the grease gun is not necessary.

Lubrication

Bearings

Joints

Chains

Challenges

- Rough use

- Temperature fluctuations, risk of damage to the installations

- High load on the systems

- High back pressure

Benefits

- Reliability: Once installed, the lubrication points are reliably supplied with lubricant and are no longer forgotten

- Flexibility: The running times are continuously adjustable from 1–12 months

- Longer service life of the systems thanks to continuous and precise lubrication

- No need to switch off the systems during maintenance

Solution

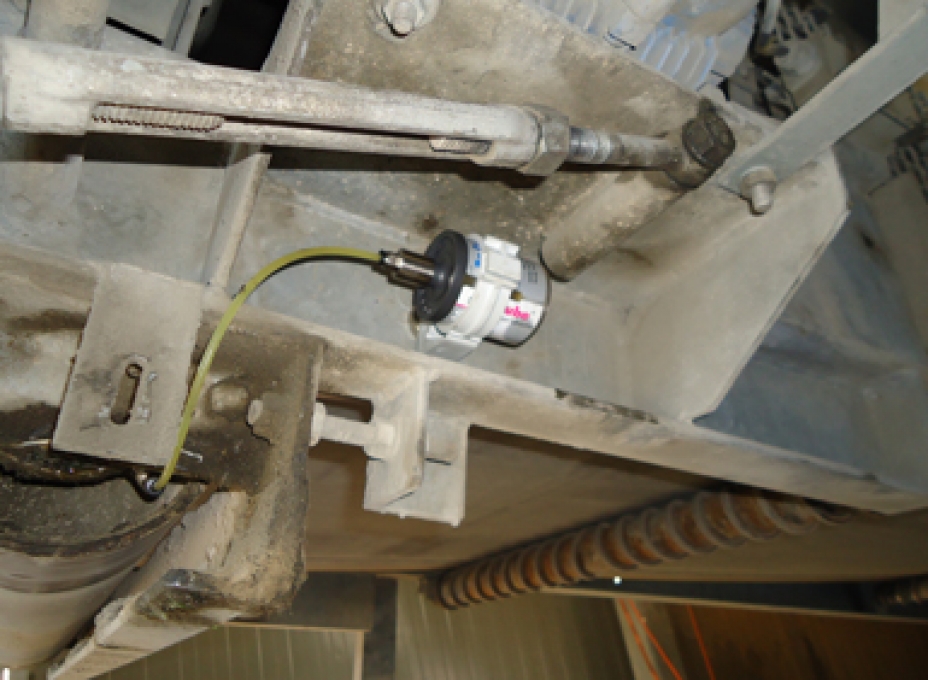

- simalube with protection against vibrations and damage

- With high back pressure IMPULSE

- Installation often removed so that the dispenser can be better protected against damage

Videos

Lubrication stockpile conveyor

Lubrication slewing ring

Lubrication conveyor belt drum

Lubrication wheel loader

Lubrication mobile crushing plant

Pressure booster up to 10 bar

Lubrication jaw crusher

Lubrication with hose

Lubrication jaw crusher pt. 2

No more manual lubrication

- Conveyor belts

- Palletizing systems

- Gearboxes

- Sieves

- Silos

- Roller screens

- Crushing plants

- Transport systems

- Rotary kilns

- Mills

- Pumps

- Motors

- Fans

Downloads