Dust, dirt and odour emissions are high in recycling plants. For this reason, continuous lubrication has many advantages. This leads to fewer business interruptions, lower maintenance costs and higher plant availability. In addition, maintenance personnel are exposed to significantly less noise, dust and the dangers of rotating system parts, which increases occupational safety.

Lubrication

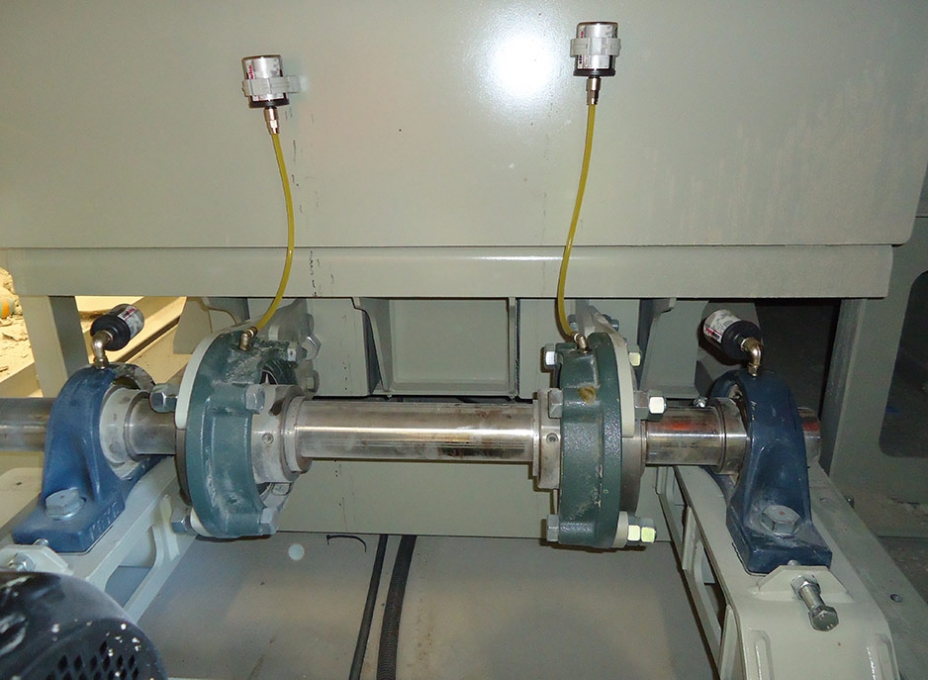

Bearings

Chains

Lifting spindles

Challenges

- Dust, dirt and odour emissions

- Equipment pollution

- Risk of damage from bulk goods etc.

- Ex environment

Benefits

- Proven lubrication system in the recycling industry

- Reduction of service and maintenance costs: there is no need for manual lubrication, so there are fewer operations and the time saved is massive

- No machine shutdown required during maintenance

- Longer service life of the systems thanks to continuous and precise lubrication

- Approved in all Ex zones

Solution

The simalubes avoid contamination.

Videos

Lubrication recycling industry

Lubrication conveyor belt drum

- Presses

- Conveyors

- Crushers

- Gearboxes

- Mills

- Motors

- Fans

- Shredders

Downloads